At C&L Rivet, one of our strengths as a manufacturer of custom cold headed parts is our ability to carry out metal part forming simulation modeling.

At C&L Rivet, one of our strengths as a manufacturer of custom cold headed parts is our ability to carry out metal part forming simulation modeling.

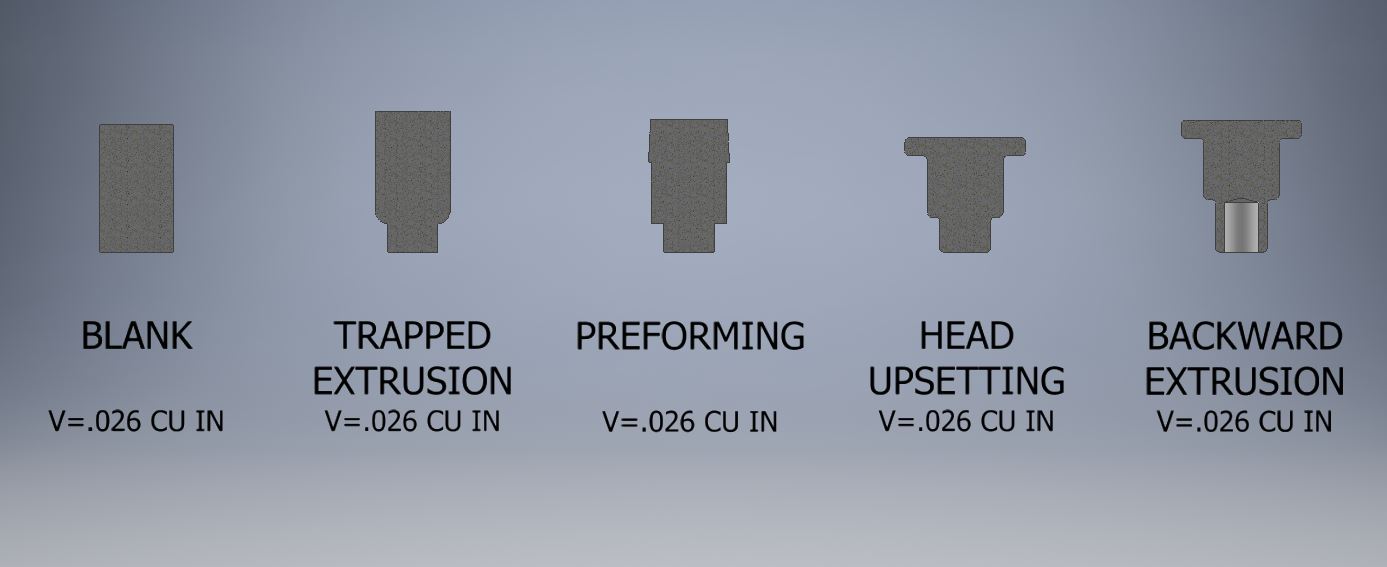

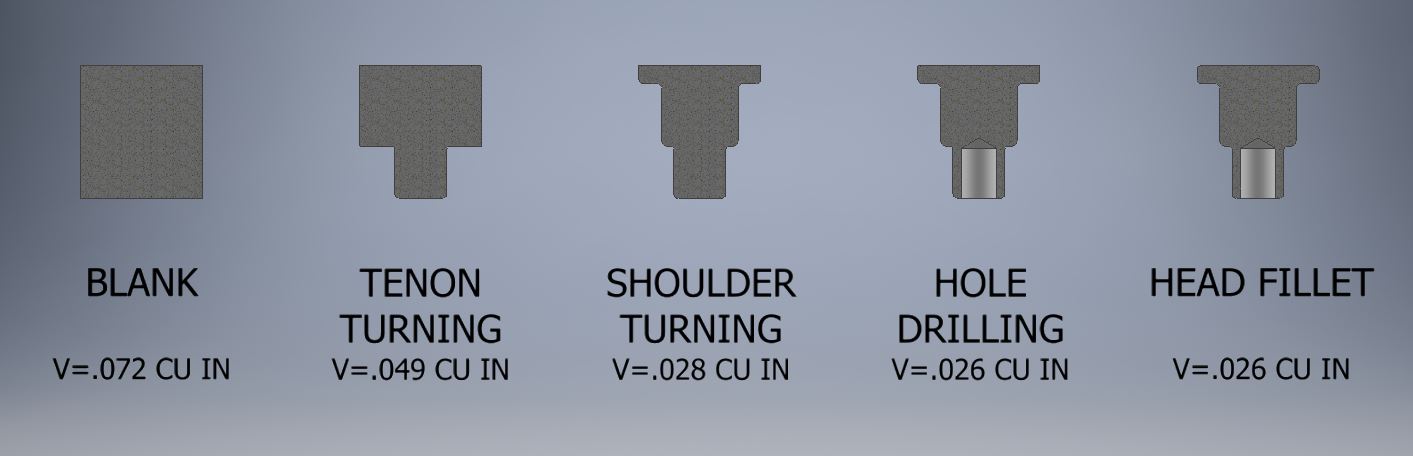

Using powerful software tools, we create animated simulations to visualize the cold forging process and observe how the metal will move under the forces and pressure. We obtain valuable insight into the process, which enables us to help customers make engineering changes that will improve part quality while also designing the forming process that is efficient, cost-effective, and maximizes yield.

As part of the process, we import dimensional drawings and use finite element analysis (FEA) to predict defects, such as excessive thinning or fracturing, as well as determine the mechanical properties of the formed part. When applicable, we supply customers with screenshots that show the various stresses and strains to demonstrate where the piece may fail. When improvements are needed, we make iterative, virtual changes to the part’s design to optimize quality. We also investigate alternate forming sequences and try out other metals. By testing different scenarios, we accelerate the process of product and tooling design while saving the expense of creating and evaluating numerous physical prototypes. With such in-depth visibility into the forging process, we can reduce the number of operations needed to form a part while also optimizing the size and shape of the blank.

We leverage our simulation capabilities to engineer fasteners, rivets, and micro-precision parts as well as the dies and tooling we use to produce them. As a valuable tool in our cold forging arsenal, simulation modeling of both the product and the process ultimately reduces costs for our customers. To learn more about our metal part forming simulation modeling capabilities, contact us today.

We leverage our simulation capabilities to engineer fasteners, rivets, and micro-precision parts as well as the dies and tooling we use to produce them. As a valuable tool in our cold forging arsenal, simulation modeling of both the product and the process ultimately reduces costs for our customers. To learn more about our metal part forming simulation modeling capabilities, contact us today.